-

Bronze CastingProcess

Bronze CastingProcess

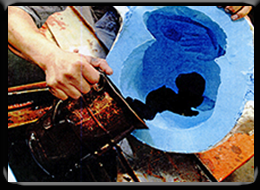

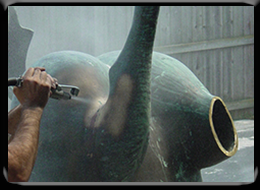

Bronze Casting Process-Lost Wax Casting

In order to transform an existing wax or clay sculpture into metal, several steps must be taken. This is known as the Lost Wax method and is a process that has been used for hundreds of years. Each step must be preformed meticulously in order to get the desired outcome.

(800) 882-5901

(800) 882-5901

Bronze Casting Process